Computed Order Tracking with Damaged Tacho Pulse

Rotating machinery can be analysed with rotation angle as the reference. This kind of reference is referred to as a tacho or key phasor, reference. A tacho signal can be analog or digital. The end result is usually Single Pulse, a Square Wave or a train of Square Waves.

Most signal analysis systems rely on the tacho pulse being in pristine condition. However, the tacho pulse may become damaged when there is sufficient vibration to shake the tacho sensor and/or the rotating system vibration is sufficient for the tacho probe to malfunction. The tacho pulse may then be damaged, and the square wave may then be missing pulses or be deformed.

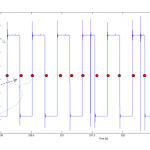

The simplest way to detect tacho is to use the gradient where a sign change is picked up and the time separation between the pulses is used to compute the RPM. This works fine with undamaged pulse trains and at stationary speeds. A slightly more refined way is to compute the time between pulses using the model RPM = (A*t + B), where A is the stationary rotation speed and B is the gradient, i.e. the rotation acceleration when B is positive or the rotation deceleration when B is negative. RPM can then be derived at high speed slope.

A next step is to use computed order tracking of prior pulses to predict the arrival of the next pulse. A missing pulse can then be corrected for and the pulse train can be repaired. Such analysis is referred to as computed order tracking with missing pulse prognosis.